English|Русский

|Site map

English|Русский

|Site map

|

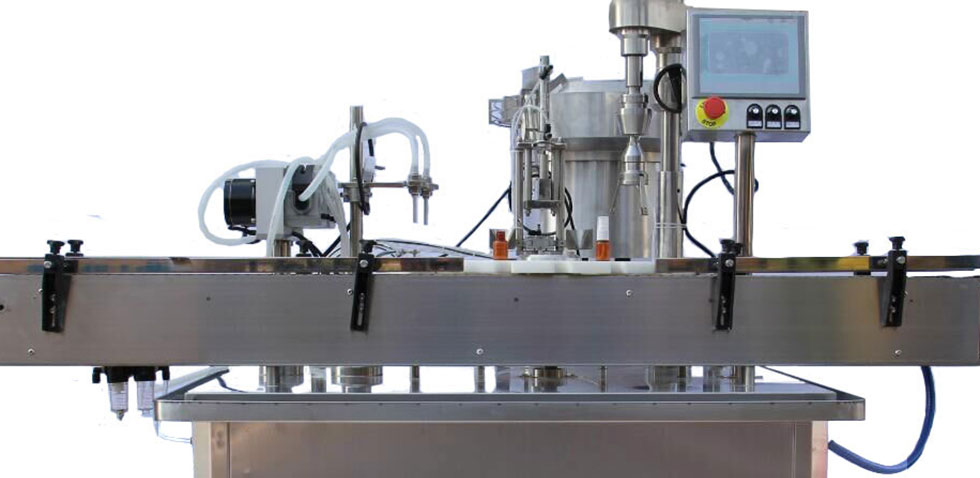

Dimension(mm) |

3000×1550×1650 |

|

Filling Range(ml) |

200-1000 |

|

Filling Speed(b/min) |

10-40 |

|

Filling Accuracy Error(%) |

±1-2 |

|

Voltage(V) |

220 |

|

Frequency(Hz) |

50 |

|

Conveying Direction |

L→R / R→L |

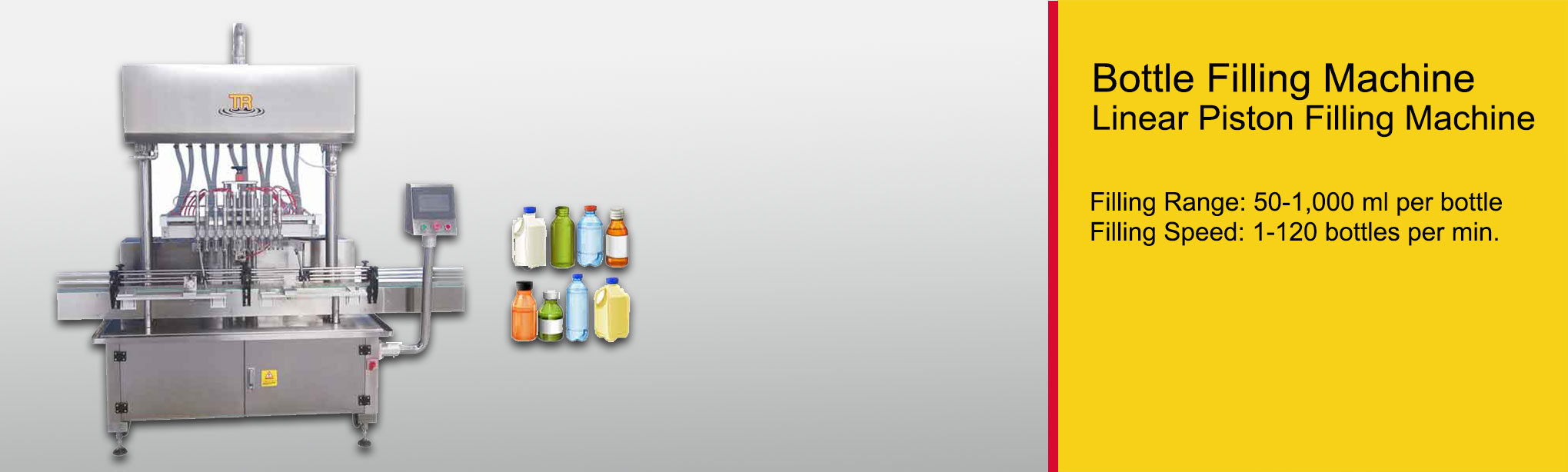

Automatic Filling Machine

-Bottle filling machine/Linear Piston Filling Machine

|

Dimension(mm) |

2000×1700×1900 |

|

Filling Range(ml) |

50-1000 |

|

Filling Speed(b/min) |

1-120 |

|

Filling Accuracy Error(%) |

±0.5-2 |

|

Voltage(V) |

220 |

|

Frequency(Hz) |

50 |

|

Working Pressure (Mpa) |

0.4-0.6 |

|

Gas Consumption (m3) |

0.1-0.5 |

|

Conveying Direction |

L→R / R→L |

Automatic Filling Machine

-Rotary Filling Machine/Planetary Filling Machine

Automatic Filling Machine- Ointment Filling Machine

Dimension(mm)

1800×750×1750

Filling Range(ml)

50-1000

Filling Speed(b/min)

1-60

Filling Accuracy Error(%)

±0.15-0.3

Voltage(V)

220

Frequency(Hz)

50

Working Pressure (Mpa)

0.4-0.6

Gas Consumption (m3)

0.1-0.5

Conveying Direction

L→R / R→L

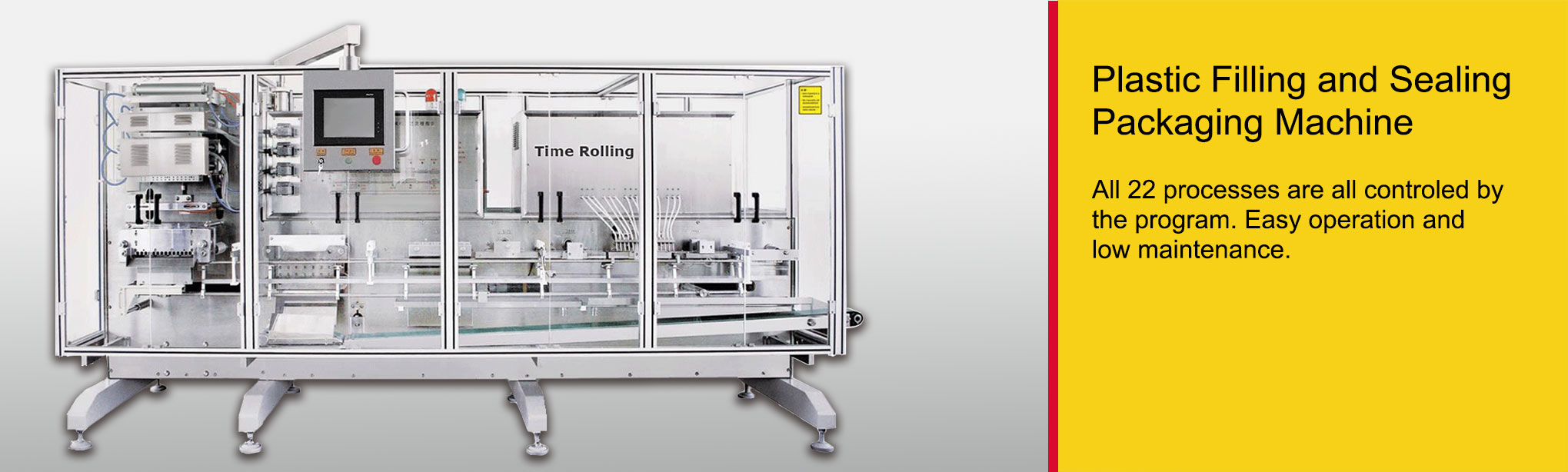

1, It is made from high-quality stainless steel as per the requirements of GMP standard.

2, All 22 processes are controlled by programming.

3, Controlled by PLC, stepless frequency conversion and variable speeds.

4, The large size touch screen is simple and easy for operation.

5, The main components of our machines are from world leading manufacturers.

6, The filling head does not drop, leak, arise bubbles or spill over.

7, It is a durable machine with low maintenance

|

Model |

PFS |

|

Max forming depth |

13 mm |

|

Cutting frequency |

<22 time/min |

|

Packing speed |

<20 plates/min 8~16 flasks/board |

|

Dimensions of pvc/pe |

0.3x345 mm |

|

Capacity |

1~60 ml |

|

Air consumption |

110 l/min |

|

Water consumption |

6 l/min |

|

Power |

380V 50Hz 12kW |

|

Size |

3,880x1,800x1,920mm |

|

Weight(kg) |

3,400 kg |

You may also like

Capsule Filling Automatic Capsule Counter Sachet Machine Capping & Labeling